|

About Products Blog Gallery Contact |

|

Home > Blog |

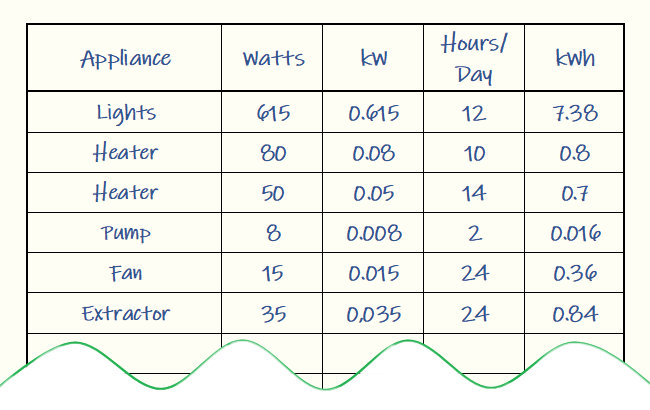

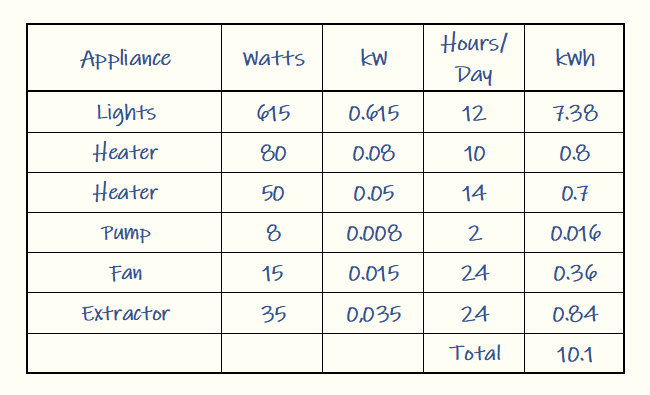

Counting the costHow to calculate the cost of powering your grow roomWith electricity prices at an all-time high, the increased cost of cultivating plants in controlled indoor environments is a concern for many growers. Modern electrical appliances may be much more efficient than previous generations of equipment, but lighting, heating, pumps, extractor fans and humidity controllers - running day in, day out - still use a substantial amount of energy. In this article, we look at how to calculate the approximate cost of powering your grow room or greenhouse for a better understanding of your energy expenditure. Step 1 - Make a list of your grow room appliances Start by making a list of all of the electrical appliances that you are using. Enter each piece of equipment into the first column of a 5-column table or spreadsheet. Give the column a suitable heading such as ‘Equipment’ or ‘Appliance’.

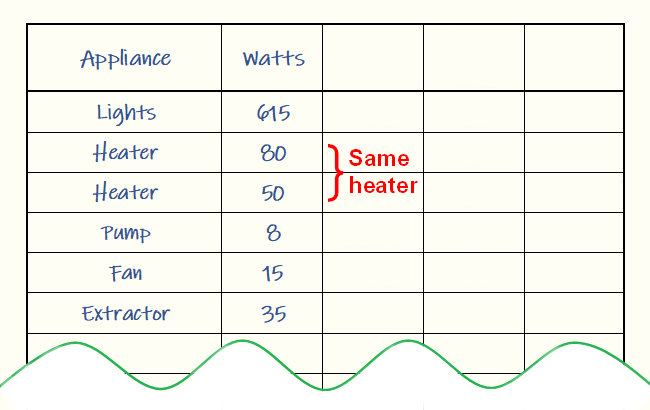

Step 2 - Find your appliances’ input power For all of the items entered in Step 1, identify the power consumption in Watts (W) from the specification label attached to the equipment. All electrical appliances should show the wattage but, if some of yours do not, you should be able to find the information in the user manual or on the supplier's website. If an appliance has a range of Watts, you will need to decide which most realistically reflects your pattern of use... Suppose, for example, that you have a heater with a high and low power setting. You can take the lowest Watts value if you always use the low setting. Take the high Watts value if you usually use the high setting, or just want to consider a ‘worst case/maximum cost’ scenario. If the heater is used on both settings - perhaps low power during the day and high power at night - you could have a row in your table for each Watt value (effectively treating your heater as two separate appliances with different power consumptions). Enter the information into the second column of your table. Give the column a suitable heading such as ‘Watts’ or ‘Power’.

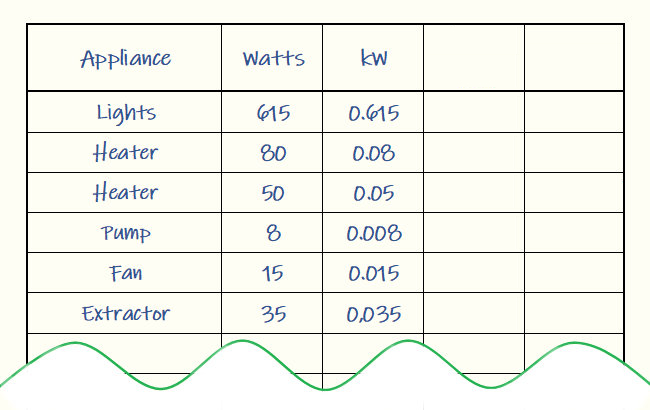

Step 3 - Convert input power to Kilowatts The values entered in Step 2 now need to be converted to Kilowatts (kW). 1 Kilowatt equals 1000 Watts, so divide the Watts figure in your second column by 1000. Enter the result into the third column of your table and give the column the heading ‘Killowats’ or 'kW'.

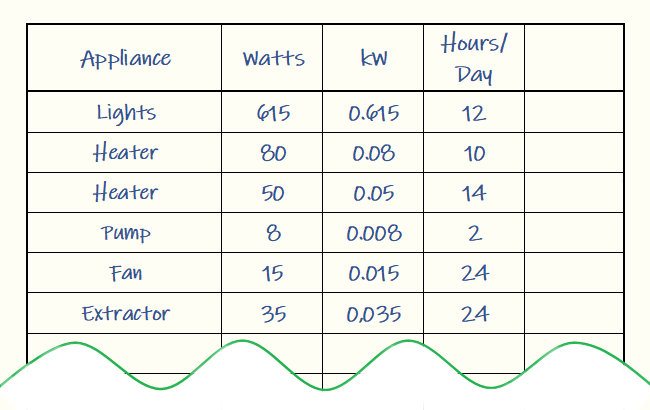

Step 4 - Estimate hours of usage The next step is to estimate how many hours each piece of equipment is in use. This can be per day, per week or per month, but you must use the same time period for every item. Enter the usage hours into the fourth column of your table. Give the column a suitable heading such as ‘Hours per day’ or ‘Hours per week’.

Step 5 - Calculate Kilowatt-Hours per appliance You now need to work out the Kilowatt-Hours (kWh) for each piece of equipment. Kilowatt-Hour is a measurement of your electric appliances’ power consumption and the amount of time that you use them. Do the calculation: Column 3 x column 4, then enter the result into the fifth column of your table. Give the column the heading ‘Kilowatt-Hour’ or ‘kWh’.

Step 6 - Calculate total Kilowatt-Hours Calculate the total Killowat-Hours for all of your equipment by adding together all the values in the fifth column of your table, then enter the sum total figure at the bottom.

Step 7 - Calculate your energy cost Finally, to establish the cost of powering your equipment, find your ‘Unit rate per kWh’ from your energy supplier. This will be shown on your contract documentation and your electricity bill; it is the price that you pay in Pence per Kilowatt-Hour. Multiply this figure by the total Kilowatt-Hours from your table, then divide the result by 100 to get a cost in Pounds. At the time of writing, an average UK domestic electricity tariff is around 34.00p per kWh. So using the example table above, the energy cost would be 10.1 kWh x 34.00p = 343.40p per day, or £3.43. Be aware that you also pay a Standing Charge (a fee to access the energy network) to your energy supplier. This, however, is charged regardless of how much electricity you use, so it is not directly attributable to your growroom or greenhouse. |

|

Website and content © Hydrocrop 2021 |